03-5577-2947

Weekdays: 9:30- 18:00

Glass Defect Analysis

セラミックフォーラム株式会社 > Ceramicforum Co., Ltd. > Products > Glass Melting Technology Department > Analysis / Simulation Service > Glass Defect Analysis

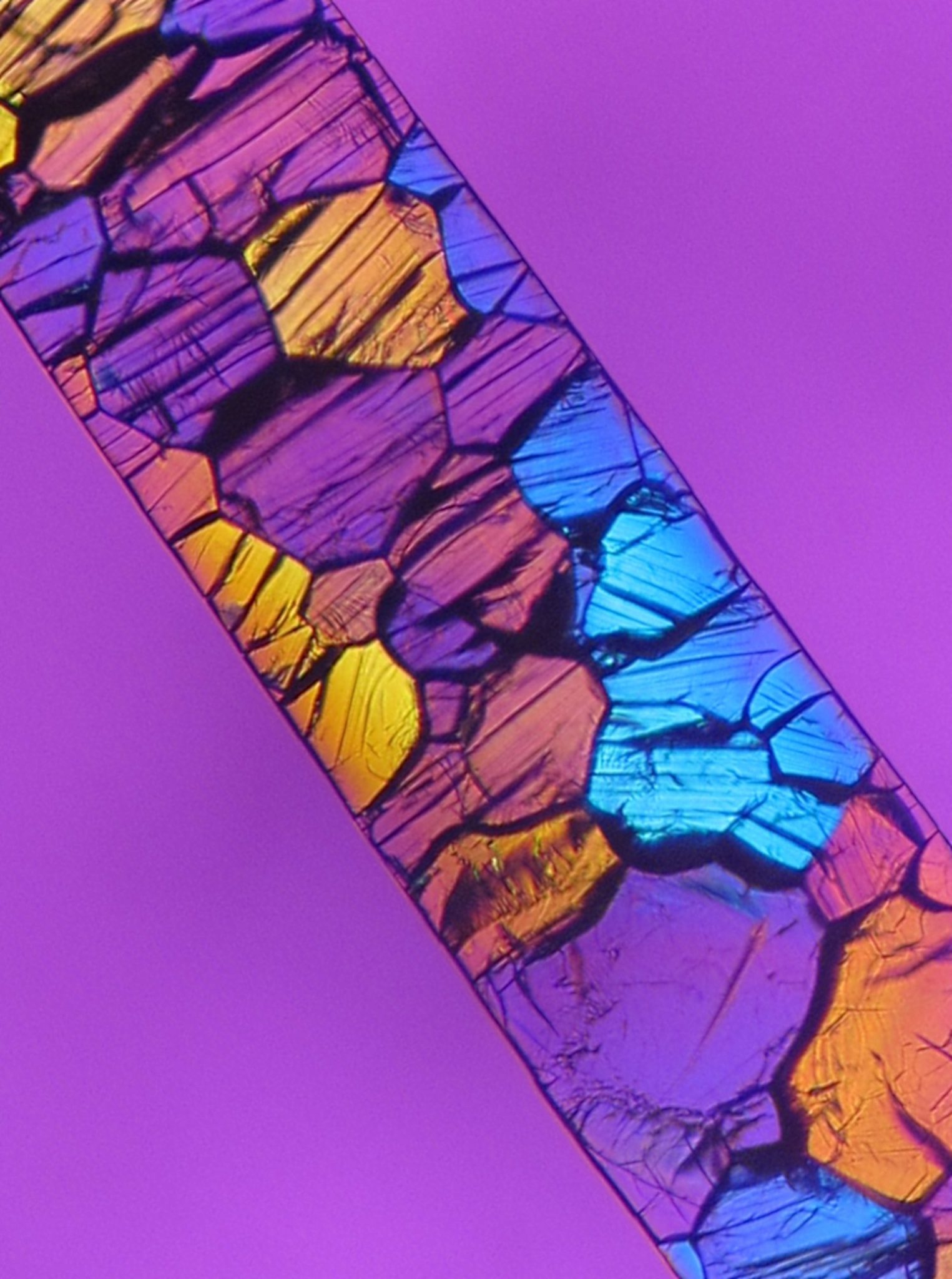

Features of Glass Defect Analysis by Glass Service

Ceramic Forum serves as a window for glass defect analysis conducted by Glass Service, Czech.

To analyze glass defects, Glass service uses methods such as bubble, stone, dissolved gas analysis, redox measuring device (Rapidox), high-temperature glass melting observation device (HTO), high-temperature glass physical property measurement etc.

Identification of bubble source is based on the following analytical data:

・Bubble gas composition (O2,N2,CO2,SO2,Ar,H2,COS,H2S,CO) are analyzed

・Internal pressure in kPa

・Interpretaion and evaluation of result based on more than 20 years of experience

Identification of bubble sources:

・Batch melting

・Reboil

・Refractory outgassing

・Electrolysis

・Mechanical Entrapment

・Redox Changes

・Water Leakage

・Glass Melt Contamination

Please do not hesitate to contact us if you are interested.

To analyze glass defects, Glass service uses methods such as bubble, stone, dissolved gas analysis, redox measuring device (Rapidox), high-temperature glass melting observation device (HTO), high-temperature glass physical property measurement etc.

Identification of bubble source is based on the following analytical data:

・Bubble gas composition (O2,N2,CO2,SO2,Ar,H2,COS,H2S,CO) are analyzed

・Internal pressure in kPa

・Interpretaion and evaluation of result based on more than 20 years of experience

Identification of bubble sources:

・Batch melting

・Reboil

・Refractory outgassing

・Electrolysis

・Mechanical Entrapment

・Redox Changes

・Water Leakage

・Glass Melt Contamination

Please do not hesitate to contact us if you are interested.

Other simulation and analysis available

Example of Glass Defect Analysis Service

We ship the glass sample provided customer to Glass Service (GS), Czech. After arriving at the GS Analysis Room, they process it into the required sample shape and measure the size of the defect GS will cut the defects in the Q mass device, quantify the gas composition inside the defect, and obtain the analysis result. Based on these results and years of experience of GS, we will send the report about the cause and solution to the defect. It will take an average of 7days to conduct the test and provide customers with result.

Manufacturer Profile

Glass Service (Czech)

Glass Service Company is a Czech company that provides glass analysis and manufactures various glass melting equipments.Glass Service aims to provide innovative products and services by combining the basic technology of glass melting and lab technology. As a main product, Glass Service manufactures an advanced control system (ES III) combining their glass manufacturing and IoT technologies.

For any questions or requests regarding our services please feel free to contact us via phone or inquiry form.

For Telephone Inquiries

03-5577-2947

Weekdays 9:30-18:00

For WEB Inquiries